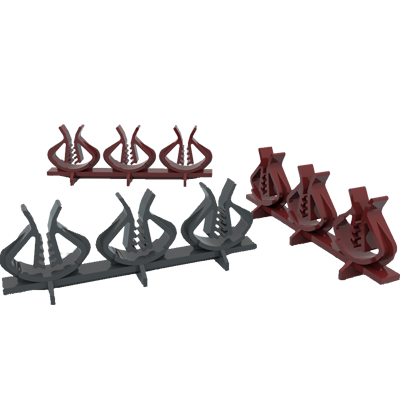

wheel fix spacer

Description

wheel fix spacer

Circular spacers are known as the Globe Fix, Solar Spacer or Spindle Spacer. The distance of the plastic maintainer will fix due to the use of vertical surfaces such as walls، columns، circular sections and … In prefabricated or prefabricated concrete, it is widely used.

Applications:

- Providing precise concrete coating on vertical surfaces

- Does not create barriers against fluid concrete

- Very strong locker in its center for rebar placement

- Resistant to vibration of concrete and vibration

- Prevents the penetration of chlorine ions, sulfates, acids and destructive agents into concrete

- Prevent the complexity of the reinforcement inside the mold

packing :

| Name | Size | Bar size | Packing (QTY) | WEIGHT (KG) |

| Wheel fix 20 | 20 | 8 – 6 | 1000 | 8/5 |

| Wheel fix 25 | 25 | 8 – 16 | 1000 | 9/2 |

| Wheel fix 30 | 30 | 8 – 20 | 750 | 8/8 |

| Wheel fix 40 | 40 | 8 – 20 | 400 | 6/8 |

| Wheel fix 50 | 50 | 8 – 20 | 300 | 6 |

| Wheel fix 50 | 50 | 10 – 28 | 200 | 5 |

| Wheel fix 60 | 60 | 8 – 20 | 200 | 6/5 |

| Wheel fix 75 | 75 | 8 – 14 | 150 | 6 |

| Wheel fix 75 | 75 | 12 – 28 | 150 | 5/8 |

| Wheel fix 100 | 100 | 12 – 28 | 100 | 7/5 |

Product Description – Wheel Fix Spacer

The appointment of concrete cover on the rebars in vertical surfaces, like other structural elements, is essential. It is often seen that in concrete walls or columns, a part of the concrete has been poured and the rusty rebar is visible at a short distance from the concrete surface. This problem is because the concrete cover for the rebar is not observed uniformly and in some sections the rebars have come closer to the surface and the standard concrete cover on the rebar has not covered it. Due to the penetration of destructive environmental factors into the concrete, corrosion of the rebars has occurred and based on this corrosion the rebar has expanded and caused the destruction of the concrete section. To form a precise concrete cover on vertical surfaces, circular spacers known as Wheel Fix plastic spacers, solar spacers or wheel spacers are used.

The Wheel Fix plastic spacer is widely used for vertical surfaces such as walls, columns, circular vertical sections, etc. in in-situ or precast concrete. Wheel Fixes are modeled and manufactured according to BSI 7973 standard so that they do not create an obstacle to fluid concrete. Wheel Fixes have a very strong lock in their center to hold the rebar. The presence of prongs around the Wheel Fixes ensures that no trace of the vibration and shock that occurs during concreting is left on the concrete surface, and thus prevents the penetration of chlorine ions, sulfates, acids and destructive agents into the concrete. Using Wheel Fix spacers on vertical surfaces creates the advantage that the rebar networks are completely parallel to the formwork and prevents the entanglement of the reinforcement inside the formwork. The load-bearing capacity of wheel fixes differs according to the diameter and size of the rebar, and depending on the size of the spacer, a special design is considered to accommodate rebar of the appropriate diameter.

In general, this piece, with its prongs on both sides, is resistant to severe vibration and shock during concrete pouring, and also prevents the penetration of ions, sulfates, acids, and other destructive factors into the concrete. This piece prevents destructive substances from penetrating into the concrete and preventing damage. Using this piece on vertical surfaces causes the rebar networks to be placed completely parallel, preventing the reinforcement from twisting inside the mold.

This Wheel Fix Spacer is one of the types of spacers for spacing rebars in reinforced concrete structures. This type of piece is modeled in the shape of a wheel and is used to maintain the exact spacing created for rebars from the concrete formwork and also to create a uniform and strong concrete cover. Due to its rotating design, this product has the ability to adjust and fix rebars at various angles and positions. Using this plastic spacer prevents common problems in reinforced concrete structures such as rebar displacement, insufficient concrete cover, and reduced durability of structures, and also improves the quality of the structure.

Wheel Fix plastic spacer usage

What is the amount of Wheel Fix spacers used per square meter?

Walls and vertical surfaces with normal force applied by concrete forms:

The consumption rate is 3 pieces per square meter for each side of the reinforced surface.

Vertical surfaces with special and heavier formwork such as tunnel formwork:

The consumption rate is 4 to 6 pieces per square meter for each side of the wall.

Columns:

Efficiency of Wheel Fix plastic spacers in columns:

The usage rate for columns up to 50×50 cm is at least 16 pieces per 3-meter column (2 pieces should be installed on each side of the yoke and repeated at every 1.5-meter height). If the column dimensions are greater than 50 cm, the number of Wheel Fix plastic spacers used in a 3-meter column may increase to 48 pieces.

How to use Wheel Fix plastic spacers

How to use the Wheel Fix plastic spacer?

Wheel Fix plastic spacers are generally installed vertically on the tie rods.

In certain structural conditions, it is possible to place a round plastic cover on the main rebars.

Learn more; Double Fix Spacer

Important points about Wheel Fix plastic spacers

What are the necessary tips about Wheel Fix plastic spacers?

- The Wheel Fix spacer is designed for use on vertical surfaces and is not suitable for use on horizontal surfaces.

- If the yoke or tensioner is located outside the reinforcement grid, the distance between the wheel fixes should be considered to be 75 centimeters.

- If the yokes or braces are inside the reinforcement mesh, the Wheel Fix plastic spacer must be installed to the main vertical rebars.

Reviews

There are no reviews yet.