Waterstop perforated sole

Description

Waterstop perforated sole

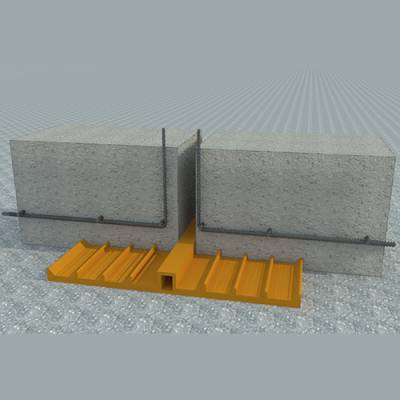

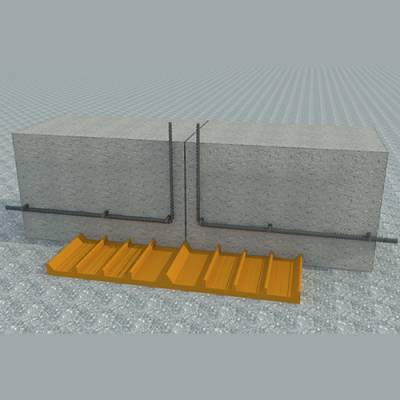

Hollow floor waterstops have treads with a high height, and also have a high thickness so that they do not lose their shape or bend during concreting, and due to having small grooves, it also prevents water penetration.

properties and effects

- High flexibility in length and width

- Resistant to acids and alkalis

- Duration of performance is equal to the life of the structure

Application

- Preventing the passage of water in the executive and expansion joints of structures

- Sealing dams, canals and concrete pipes

- Sealing artificial pools and lakes

packing

25 meter rolls

Waterstop Perforated Sole – High-Reliability Joint Sealing for Concrete Structures

The Waterstop Perforated Sole is a high-performance, heavy-duty sealing solution engineered specifically for horizontal construction joints in concrete slabs where water ingress poses a significant risk. This waterstop variant features a hollow body with deeply grooved, raised treads, providing exceptional mechanical anchorage to the concrete and preventing slippage or displacement during pouring and compaction.

Its perforated, treaded design is a key innovation: the small grooves and high-profile ridges allow the waterstop to interlock mechanically with the surrounding concrete, increasing bonding and reducing the risk of water bypassing through the joint line. The high thickness and rigidity of the product ensure that it maintains its shape and position even under intense pressure and vibration during concreting.

Properties and Effects

- Exceptional Dimensional Stability: With an extra-thick profile and reinforced tread pattern, this waterstop resists deformation or bending during concrete placement, ensuring accurate alignment and joint sealing.

- Superior Flexibility in All Directions: Offers excellent adaptability in both longitudinal and transverse directions, enabling smooth installation across curved or irregular joint geometries.

- Long-Term Durability: The performance lifespan of the perforated sole waterstop is equivalent to the life of the structure itself, thanks to its UV-stabilized and chemical-resistant PVC compound.

- High Chemical Resistance: Capable of withstanding prolonged exposure to acids, alkalis, chlorides, and other corrosive agents typically found in treated water, wastewater, and industrial environments.

- Enhanced Water Sealing Performance: The micro-grooves and deep tread patterns act as capillary barriers, making it nearly impossible for water to migrate through the concrete joint under hydrostatic pressure.

- Heat and Cold Tolerant: Maintains flexibility and sealing performance in extreme temperature conditions, making it suitable for both tropical and cold climates.

Applications

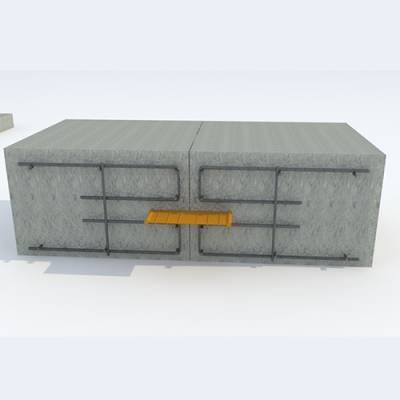

This type of waterstop is ideal for use in hydraulic, industrial, and architectural concrete structures, especially in horizontal and expansion joints. Its superior sealing capability and structural integrity make it essential for projects where water containment and structural longevity are critical. Applications include:

- Sealing Expansion and Construction Joints: Prevents water migration at critical interfaces between concrete slabs and poured walls.

- Dams, Spillways, and Irrigation Canals: Withstands heavy hydrostatic pressure and movement in large hydraulic infrastructure.

- Concrete Pipes and Precast Sections: Provides sealing at the joint lines in large-diameter concrete piping systems.

- Artificial Lakes, Reservoirs, and Reflecting Pools: Maintains waterproofing over extended surfaces and curved perimeters in landscape and recreational structures.

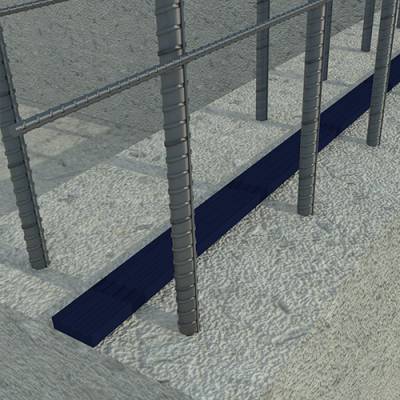

- Underground Structures and Foundations: Prevents groundwater penetration into basements, tunnels, and retaining walls.

- Sewage and Wastewater Treatment Plants: Resistant to chemical attack, ensuring long-term sealing in harsh waste-handling environments.

Advantages Over Conventional Waterstops

- Increased Mechanical Bonding: Unlike flat or smooth waterstops, the perforated sole variant offers more aggressive anchorage into the concrete, reducing displacement during concrete flow.

- Reduced Risk of Water Channeling: The geometry of this waterstop disperses hydraulic pressure and blocks water pathways more efficiently than standard types.

- No Need for Additional Fixing Devices: Its high rigidity and structured profile allow for secure placement without clips or brackets in most use cases.

- Easy Integration with Steel Reinforcement: Can be placed around or through rebars without loss of sealing efficiency.

Installation Tips

- Center the Waterstop in the Joint: For best results, position the waterstop precisely at the midpoint of the joint width during formwork preparation.

- Secure Before Pouring: Use temporary ties or spacers if needed to keep the waterstop firmly in place until the concrete is partially set.

- Overlap with Heat Welding or Solvent Welding: For continuous joint sealing, ensure all splices and corners are joined using approved thermal welding or PVC-compatible adhesives.

Technical Specification & Packaging

| Description | Thickness (mm) | Roll Length |

|---|---|---|

| Waterstop Perforated Sole | 5 – 6 mm (nominal) | 25 meters |

The product is supplied in standard 25-meter rolls, tightly coiled and protected for transport. Custom sizes, hole patterns, and colors are available on request to match specific project requirements.

Why Choose Perforated Sole Waterstop?

Choosing the Waterstop Perforated Sole means you’re investing in a proven, premium-quality solution for long-term waterproofing of concrete joints. It ensures:

- Long-term water resistance

- Seamless integration in reinforced concrete

- Zero compromise on structural performance

- Reduced maintenance and repair costs

- Full compliance with international waterproofing standards

Its robustness and design make it a go-to solution for civil engineering, infrastructure, water management, and heavy construction projects where safety, durability, and efficiency are non-negotiable.

Waterstop Perforated Sole – Advanced Horizontal Joint Seal for Concrete Structures

Waterstop Perforated Sole is a highly engineered waterproofing component designed for horizontal construction joints in reinforced concrete systems. Characterized by its thick, grooved, and high-profile body, it provides an effective and durable barrier against water infiltration. This product is especially tailored for areas exposed to hydrostatic pressure, joint movement, or harsh environmental conditions, where traditional waterstops may fail to deliver long-term sealing performance.

This waterstop features a hollow core profile with aggressive ribbing and precisely spaced micro-grooves across its surface. The combination of its elevated tread pattern and perforations ensures maximum mechanical interlock with poured concrete, significantly minimizing any risk of displacement or deformation during high-volume concrete casting.

Key Properties and Functional Advantages

- Robust Dimensional Stability: Its reinforced profile, with a thickness of 5 to 6 mm, ensures consistent placement and resistance to folding, warping, or collapse under concrete pressure.

- Flexible Yet Strong: Engineered for multidirectional flexibility, this waterstop easily conforms to complex geometries without compromising its sealing capabilities.

- Chemical and pH Resistance: Built from high-grade thermoplastic or polyvinyl chloride (PVC) compounds resistant to aggressive chemical agents including industrial acids, alkalis, chlorine, and sulfate-based compounds.

- Thermal Endurance: Maintains flexibility and sealing integrity across extreme temperature fluctuations (ranging from -20°C to +80°C), making it suitable for tropical heat and sub-zero applications alike.

- Permanent Bonding: Its mechanical grip ensures the waterstop becomes an integral part of the structure, offering lifelong performance that matches the design life of the structure itself.

- Hydrostatic Pressure Resistance: Withstands high water pressure conditions, preventing water migration even under submerged or saturated environments.

Wide-Ranging Applications

Waterstop Perforated Sole is suitable for a wide variety of infrastructure and architectural applications where moisture control is crucial:

- Construction and Expansion Joints: Installed at slab-to-wall or slab-to-slab interfaces in both cast-in-place and precast concrete systems.

- Hydraulic Structures: Ideal for dams, spillways, retention basins, and irrigation channels where constant water flow and pressure are present.

- Wastewater and Sewage Facilities: Effectively seals joints in treatment tanks, clarifiers, and underground vaults, resisting chemical degradation.

- Artificial Ponds and Landscape Pools: Provides seamless waterproofing for ornamental lakes, eco-parks, and public fountains.

- Concrete Pipe Systems: Ensures watertight seals in large-diameter stormwater drains, culverts, and precast pipe assemblies.

- Underground and Foundation Waterproofing: Protects subterranean areas such as basements, subways, and utility corridors against groundwater intrusion.

- Industrial Flooring and Retaining Walls: Guarantees long-term durability in high-load areas subject to thermal expansion and contraction.

Comparative Advantages Over Traditional Waterstops

- Improved Bonding Geometry: The perforated and grooved surface provides better adhesion than flat or smooth profiles.

- No Slippage During Pouring: Resists shifting even when subjected to high-vibration concrete vibrators and pour rates.

- Low Installation Error Risk: Maintains its shape without the need for metal clamps or external positioning tools.

- Better Compatibility with Reinforcement: Can be looped or tied through rebars without damaging the waterstop or reducing performance.

- Labor Efficiency: Reduces time needed for alignment, securing, and post-casting inspection due to its high rigidity and stability.

Installation Guidelines

For optimal sealing performance, follow these best practices during the installation of Waterstop Perforated Sole:

- Placement Accuracy: Ensure the waterstop is perfectly centered along the joint, extending equally into both sides of the concrete pour.

- Fixing Options: Use temporary ties, binding wire, or integrated clips to keep the waterstop secure before and during pouring.

- Joint Welding: Where continuous length is needed, join the ends using thermal welding (hot blade method) or solvent-based adhesives approved for PVC-based waterstops.

- Formwork Integration: Integrate within formwork such that it remains exposed for joint overlap in multi-stage casting operations.

Technical Specifications

| Product Name | Thickness (mm) | Roll Length (m) |

|---|---|---|

| Waterstop Perforated Sole | 5 – 6 | 25 |

- Material Composition: Flexible, UV-stabilized thermoplastic (PVC or TPE)

- Color: Standard colors include black, blue, and yellow (custom colors on request)

- Shore A Hardness: Typically between 70–80

- Tensile Strength: >12 MPa

- Elongation at Break: >250%

- Density: Approx. 1.3 – 1.4 g/cm³

Packaging & Storage

Each roll is tightly wound and packaged in moisture-protected, UV-resistant wrapping for safe transportation and long-term storage. Store in a cool, shaded location, away from direct sunlight and sharp objects. Shelf life is up to 36 months when kept under proper conditions.

Why Specify Perforated Sole Waterstops for Your Project?

- Certified Quality: Manufactured to meet global construction and waterproofing standards (ASTM, DIN, BS)

- Construction Reliability: Trusted in thousands of critical infrastructure projects worldwide

- Zero Rework Rate: Reduces need for secondary waterproofing membranes or chemical sealants

- Structural Safety Assurance: Prevents water-related deterioration such as concrete spalling, steel corrosion, and freeze-thaw damage

- Cost Efficiency: Cuts future maintenance and repair costs by ensuring complete joint protection from the start

Waterstop Perforated Sole – Ultimate Sealing Solution for Horizontal Concrete Joints

Waterstop Perforated Sole is an advanced and high-reliability waterproofing system, purpose-built to provide long-term protection for horizontal construction joints exposed to water infiltration. Designed with a unique hollow profile, deep grooves, and high tread patterns, this waterstop creates a strong mechanical bond with concrete, effectively sealing construction and expansion joints against water, chemicals, and environmental stressors.

The perforated and treaded configuration not only enhances mechanical interlocking but also distributes hydrostatic pressure, drastically reducing the possibility of leakage through concrete joints even under the most demanding conditions. Its robust structure prevents deformation during pouring, ensuring maximum reliability during concrete placement.

Unique Features and Functional Benefits

- Exceptional Dimensional Stability

Thanks to its high-thickness profile (5–6 mm nominal) and heavily reinforced ribs, Waterstop Perforated Sole maintains precise alignment throughout the concreting process, resisting any warping, bending, or collapse under the intense pressures of pouring and vibration.

- Superior Flexibility Across Axes

The material’s flexible design allows it to adapt to both longitudinal and transverse movements. This makes installation across curves, corners, and non-linear joints seamless and maintains continuous waterproofing without gaps or weaknesses.

- Long-Term Durability

Engineered from UV-stabilized thermoplastic PVC or TPE compounds, this waterstop delivers a service life that matches or exceeds the design life of the structure. Its resilience to environmental degradation ensures consistent performance over decades.

- Chemical Resistance

Waterstop Perforated Sole is formulated to resist chemical attack from acids, alkalis, chlorides, and sulfate-rich environments, making it ideal for use in wastewater treatment facilities, chemical plants, and industrial complexes.

- Hydrostatic Pressure Defense

The combination of deep ribs and micro-grooves acts as a capillary barrier, preventing water seepage even under constant hydrostatic pressure. This makes it a perfect solution for submerged structures.

- Thermal Stability

Designed to perform reliably within a wide range of temperatures, from -20°C to +80°C, the Waterstop Perforated Sole is equally suited for arid, tropical, or freezing climates.

- Mechanical Interlock Advantage

Unlike smooth-surfaced waterstops, the perforated design dramatically improves mechanical grip within concrete, minimizing slippage and ensuring maximum sealing efficiency during setting and curing.

Applications

Waterstop Perforated Sole is a critical component for various civil, industrial, and architectural projects where waterproofing integrity is paramount:

- Construction and Expansion Joints: Effective sealing of joints between slabs, walls, and floors in cast-in-place and precast structures.

- Hydraulic Structures: Ideal for use in dams, spillways, flood barriers, irrigation channels, and stormwater management systems where high water pressure is common.

- Water and Wastewater Treatment Plants: Resistant to chemical exposure and water pressure, protecting tanks, basins, and conduits.

- Artificial Ponds, Reflecting Pools, and Lakes: Ensures watertight construction in landscaping and recreational water bodies.

- Concrete Pipelines and Culverts: Provides reliable sealing at connection points in large-diameter concrete pipes.

- Underground Constructions: Safeguards basements, tunnels, subways, and parking structures from groundwater ingress.

- Industrial Foundations and Flooring: Handles thermal and structural movement without compromising waterproofing.

Advantages Over Traditional Waterstops

- Higher Bond Strength: Deep grooves and perforations significantly outperform smooth profiles in bond strength and sealing reliability.

- Reduced Installation Errors: High stiffness reduces the need for additional fixing hardware, making installation quicker and more error-proof.

- No Displacement During Pouring: Resists movement even under heavy use of concrete vibrators and rapid concrete placement.

- Ease of Integration with Rebars: Easily positioned around or through reinforcement without sacrificing performance or causing damage.

- Labor and Cost Efficiency: Faster installation with reduced need for post-casting corrections or repairs.

Installation Guidelines

To achieve the best performance, meticulous installation practices are recommended:

- Center Positioning: Always position the waterstop at the center of the joint line to ensure maximum waterproofing performance.

- Secure Pre-pour: Use temporary ties, spacer bars, or formwork clips to hold the waterstop firmly in place during initial concrete pours.

- Correct Joint Welding: For extended runs, join waterstop ends by heat welding using a thermal knife or by applying PVC-compatible solvent adhesives. Proper jointing ensures continuous waterproofing across sections.

- Formwork Alignment: Waterstop should remain properly aligned and visible in the joint area for subsequent concrete pours in multi-phase constructions.

Technical Specifications

| Product | Thickness (mm) | Roll Length (m) |

|---|---|---|

| Waterstop Perforated Sole | 5 – 6 mm | 25 meters |

Material Composition: High-grade flexible thermoplastic (PVC or TPE)

Shore A Hardness: 70–80

Tensile Strength: >12 MPa

Elongation at Break: >250%

Density: 1.3–1.4 g/cm³

Color Options: Standard colors are black, blue, and yellow; custom colors available on request.

Packaging: Rolls are moisture-protected and UV-shielded for safe transport and storage.

Storage Recommendations

To maximize shelf life and maintain product quality:

- Store rolls in a cool, shaded, and dry environment.

- Avoid prolonged exposure to direct sunlight and high temperatures.

- Keep away from sharp or abrasive objects that could damage the material.

- Under ideal conditions, the shelf life can exceed 36 months.

Why Choose Waterstop Perforated Sole for Your Project?

Selecting Waterstop Perforated Sole for your project guarantees:

- Unmatched Water Tightness: Forms a complete barrier against water passage across structural joints.

- Long-Term Structural Integrity: Reduces risks like concrete spalling, reinforcement corrosion, and frost damage.

- Superior Installation Efficiency: Simplifies setup, even in complex geometries and reinforcement-dense areas.

- Compliance with International Standards: Meets or exceeds ASTM, DIN, and BS standards for waterstops and concrete joint sealing products.

- Lower Lifecycle Costs: Reduces future expenses for maintenance, repair, or retrofitting secondary waterproofing layers.

Whether you are designing a high-rise basement, a massive dam structure, a wastewater treatment facility, or an ornamental lake, Waterstop Perforated Sole offers the assurance of lasting waterproofing security and structural reliability.

Reviews

There are no reviews yet.