Waterstop Clamp

Description

Waterstop Clamp

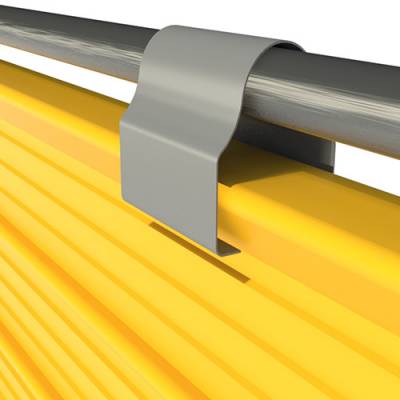

Clamp Waterstop or Best Waterstop is made of steel plate and is the best method of attaching to the rebar network for waterstop edges.

Features:

- Provides higher strength

- Makes it easy to install and run

- It has little weight

Package:

1000pcs in box

Product Description – Waterstop Clamp

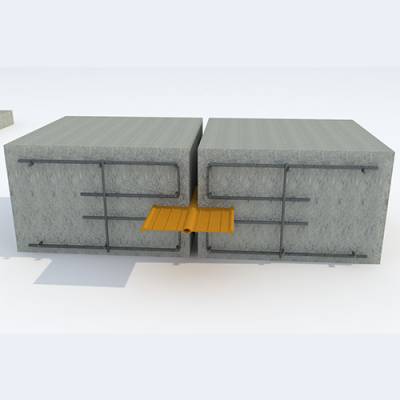

The waterstop clamp or waterstop fastener is formulated and manufactured from sheet steel and is the best method for connecting the edges of the waterstop to the rebar network.

To install the water stop to the rebar structure, an auxiliary rod is needed to place the water stop clamp on it, and finally the PVC water stop sealing strip is bonded to the rebar network by pressing the jaws of the water stop metal clamp.

It is recommended to place one water stop clip on each side for every 50 centimeters of water stop length.

In some cases, it is considered to connect the waterstop to the rebar network using wire, but this method is not recommended in any way.

Because by drilling a hole in the water stop and passing the wire through, there is a possibility of stretching due to concreting and ultimately tearing the water stop.

To install a waterstop to a rebar structure using wire, the edges must first be punched at regular intervals and with a specific diameter, and finally a special steel ring must be placed inside the holes created and compressed so that the waterstop has sufficient strength and resistance to tearing as the wire passes through.

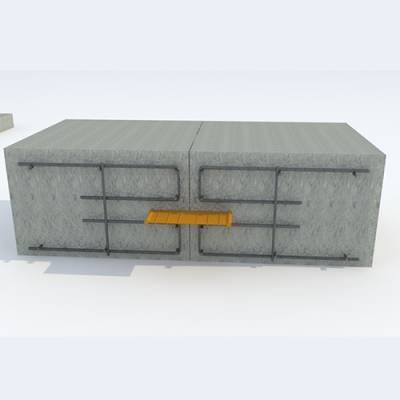

However, the best way to keep the waterstop inside the rebar rack until concreting is done is to connect the waterstop to the rebar structure using the waterstop’s metal clamp.

In this connection method, the possibility of the PVC Waterstop sealing tape separating or tearing during concreting is low.

Waterstop clamp packaging

Pack of 1000

Waterstop clamp feature

What are the features of the Waterstop clamp?

- It maintains the waterstop strips.

- Fixes the edges of the sealing tape.

- Prevents damage to the sealing tape.

- It causes proper welding and bonding of waterstop strips.

- It prevents the waterstop from separating or falling off.

Waterstop Clamp – High-Strength Connection for PVC Waterstop Installation

The Waterstop Clamp (also known as Clamp Waterstop or Best Waterstop Clamp) is a specialized fastening tool made from high-quality sheet steel, meticulously engineered to ensure a strong, durable, and reliable attachment of PVC waterstop edges to the rebar network in concrete structures.

This method provides a significantly superior alternative compared to conventional techniques such as wiring, minimizing risks associated with tearing or displacement during the concreting process.

By utilizing the Waterstop Clamp, installation becomes faster, cleaner, and structurally sound, ensuring the long-term performance of the waterproofing system embedded within construction joints.

Key Features of Waterstop Clamp

- Superior Mechanical Strength:

Fabricated from robust steel plates, these clamps offer exceptional resistance to the mechanical stresses experienced during concrete pouring and setting. - Simplified Installation Process:

Thanks to their ergonomic design, Waterstop Clamps allow for quick and hassle-free mounting of waterstop strips onto the rebar framework without the need for specialized tools. - Lightweight and Practical:

Despite their solid build, the clamps are lightweight, making handling and transport easier, especially in large-scale construction projects. - Enhanced Stability During Concreting:

The clamps securely anchor the waterstop in place, effectively preventing any unwanted movement, deformation, or tearing when fresh concrete is poured. - Preservation of Waterstop Integrity:

Unlike wire fastening, no drilling, punching, or compromising of the waterstop material is required, maintaining the continuous waterproofing performance.

Packaging Details

- Packaged in Boxes of 1000 Pieces

- Each clamp is precision-manufactured for consistent performance

- Vacuum-sealed for long-term storage and protection from corrosion

Product Description – Waterstop Clamp

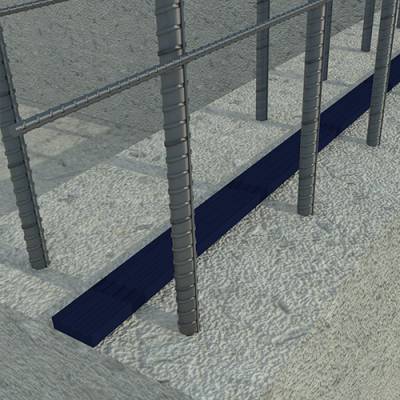

The Waterstop Clamp is specifically developed to address the common challenges faced during the installation of PVC waterstops in reinforced concrete structures. Traditional methods—such as tying with wire—often involve creating holes in the waterstop strip, which inherently weakens the sealing barrier and exposes it to potential tearing under concrete pressure.

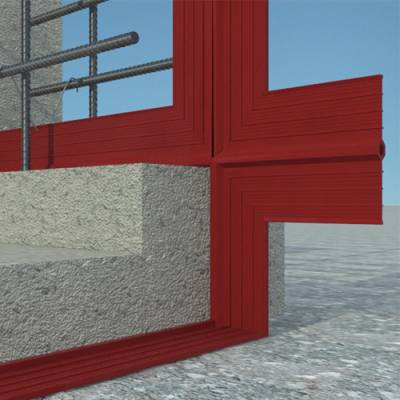

In contrast, the Waterstop Clamp system ensures that the sealing strip remains intact and fully functional, maintaining a continuous waterproof barrier across expansion joints, construction joints, and other critical points.

Installation Instructions for Waterstop Clamp

- Preparation:

Place an auxiliary rod or similar support structure parallel to the rebar mesh where the waterstop needs to be fixed. - Positioning:

Align the PVC waterstop strip along the rebar framework, ensuring proper centering relative to the future joint line. - Clamping:

Using the Waterstop Clamps, press the jaws over the edges of the waterstop and the auxiliary rod to create a firm, reliable connection. - Spacing Recommendation:

For optimal results, it is recommended to install one Waterstop Clamp approximately every 50 centimeters along both sides of the waterstop strip.

This method guarantees that the sealing tape remains firmly positioned during concrete placement, thereby eliminating the risk of misalignment, shifting, or material failure under the hydrostatic pressures exerted by wet concrete.

Comparison with Traditional Wire Fastening

In some outdated practices, wires are used to attach waterstops by puncturing holes and threading the wire through. However, this technique has several major disadvantages:

- Material Weakening:

Drilling holes into the waterstop severely compromises its structural integrity, creating points of weakness. - Tear Risk:

During the intense pressure and movement of fresh concrete, these perforations act as tearing points, leading to premature failure. - Complex Reinforcement Requirements:

To mitigate these risks, additional steps such as inserting steel rings into the punctured holes are needed, increasing labor time and cost.

In contrast, the Waterstop Clamp Method eliminates these risks entirely by preserving the full strength of the waterstop without invasive modifications, while providing a faster, safer, and more reliable installation technique.

Waterstop Clamp Features at a Glance

- Secure Retention:

Firmly holds waterstop strips against the rebar, preventing displacement. - Edge Stabilization:

Maintains the precise alignment and stability of the waterstop edges throughout the concrete pouring process. - Damage Prevention:

Protects the integrity of the PVC waterstop material by avoiding perforations or physical deformation. - Facilitates Stronger Joints:

Ensures that multiple waterstop strips can be accurately welded or bonded together for long stretches of construction joints. - Minimizes Project Delays:

Reduces installation errors and rework, helping contractors meet tight construction schedules. - Long-Term Waterproofing Assurance:

Enhances the performance and lifespan of the waterproofing system within the structure.

Conclusion

When it comes to embedding PVC waterstops securely and effectively within concrete structures, Waterstop Clamps offer a superior fastening solution. They deliver the strength, durability, and reliability needed to ensure long-term waterproofing protection while simplifying the installation process and eliminating unnecessary damage risks.

Choosing Beton Plast’s Waterstop Clamp is an investment in construction quality, operational efficiency, and structural durability.

Reviews

There are no reviews yet.