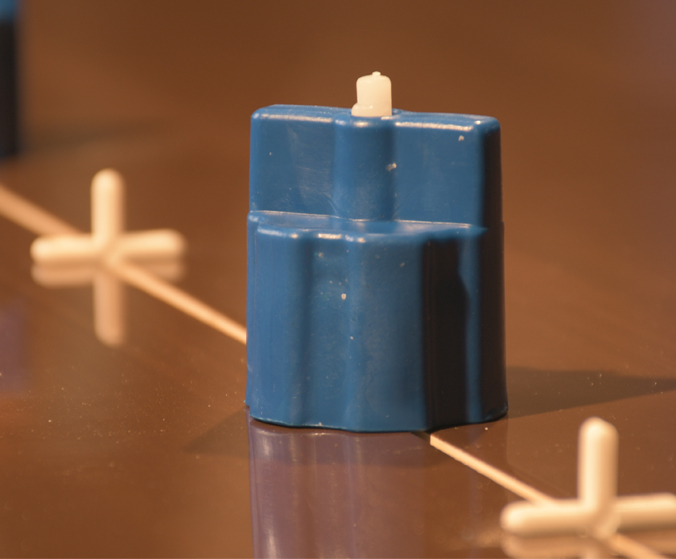

Tile corner strip

Description

Tile corner strip

The corner strip is used at the beginning and end of tiling or stone work and helps the beauty of the work. Basically, in the positive corners of the edges of the tile, the two edges of the tile or ceramic that meet do not show an interesting appearance, and the corners need to be properly covered.

properties and effects

- This piece can be ordered and made in different sizes.

- It is very resistant to rust, color and breakage.

- Using high-quality materials makes it have a long life.

Application

- It increases the strength and durability of the work.

- It creates a cover for the tiles that matches its design and color.

- It is used as a protector to prevent chapped lips and future injuries.

Package:

It is customized

Product Description – Tile Corner Strip

What is a tile corner strip?

Tile and ceramic corner strips are known by various names such as tile and ceramic edging, tile corner strips, etc. The corner strips are used at the beginning and end of tiling or stonework and make the work more beautiful. Usually, in the positive corners of the tile edges, the two edges of the tile or ceramic that meet do not show an interesting appearance and the corners need to be covered properly. Also, during tiling, the tiles and ceramics placed in the corners and corners of the wall have sharp edges due to cutting, and in addition to being difficult to handle, they are not glazed well, and it is also difficult to cover these edges with jointing mortars. To solve this problem, tile corner strips, or tile edging, have been produced and presented. Tile corner strips allow the edges to be covered without cutting the edges of the tiles and ceramics. In addition to being used in tiles and ceramics, ceramic corner strips can also be used for stone and wood. Ceramic corner strips are usually made of two types of steel corner strips and PVC corner strips and are produced in a variety of colors. Depending on the design of the tile and ceramic surface, the appropriate corner strip can be selected so that we can witness double beauty at the edges and corners. Another use of tile corners or ceramic corner strips is to use them as a block, because they have good stability and stability when used and are a good option for use as a vertical block for the tiler. Another use of ceramic tile corners is to use them as a block during installation. Ceramic tile corners remain firm and stable during tiling and also provide the possibility of using them as a vertical block by the tiler. As mentioned, tile corner strips are designed and produced from two types of galvanized steel and PVC, which have high resistance to different weather conditions and are not subject to rust.

In general, in fact, tile spacers are a construction tool that is used in building joinery. It is designed in such a way that after the construction process is completed, it is used as a corner strip on the edges of walls, tiles, etc. In fact, this piece increases the strength of the work, protects sharp edges, and covers corners. It can also reduce building vibrations.

The vertical edging, also known as the corner strip or edge strip, is an important element in the installation of ceramic tiles. This strip is used to create smooth and neat edges, protect the corners of the tiles, and improve the final appearance of the installation surface. Using this piece is one of the effective ways to improve the quality and durability of the installation of tiles and ceramics, and creates a professional and clean final appearance.

How to use tile corner tape

How can corner tape be used?

Corner tape is one of the best-selling equipment and supplies used in the construction industry, which is widely used in the joinery stage and creates a beautiful appearance for you.

Corner strips have one or two corners that are placed between the tile adhesive and under the adjacent tiles and are fixed between two tiles. These strips are installed as part of the ceramic tile after it has dried and cannot be easily removed if you damage the surrounding ceramic tile.

Tile corner strip consumption

How much corner tape is used?

The amount of corner tape used depends on the width and length of the desired surface.

Product Description: Tile Corner Strip

What is a Tile Corner Strip?

Tile corner strips, also known as tile edge profiles or ceramic edging strips, are specialized components used primarily at the beginning and end of tiling or stonework projects to create a refined and professional finish. When two edges of tiles or ceramics meet at positive corners, their intersection often lacks aesthetic appeal and may expose rough or unpolished edges. In such cases, a corner strip effectively conceals these imperfections, resulting in a clean and seamless transition between surfaces.

Beyond enhancing the beauty of tile installations, tile corner strips provide a crucial protective role. The sharp, exposed edges of tiles, especially after being cut for fitting, are vulnerable to damage and pose safety risks such as chipping and personal injury. Tile corner strips address these challenges by offering a durable, protective cover that shields the edges while harmonizing with the overall design.

These strips are essential components not only for ceramic and porcelain tiles but also for stone, wood panels, and other decorative surfaces. Depending on the material and project requirements, tile corner strips are available in a variety of materials including PVC, anodized aluminum, stainless steel, and sometimes even brass, each offering unique aesthetic and functional properties.

Properties and Effects

Tile corner strips are engineered to meet the highest standards of durability and performance:

- Material Variety: Available in stainless steel, galvanized steel, high-grade PVC, and anodized aluminum, offering excellent options for indoor and outdoor use.

- Rust and Corrosion Resistance: Especially the metallic versions exhibit exceptional resistance to moisture, oxidation, and harsh weather conditions, ensuring long-term durability.

- Color Fastness: Designed to resist fading, discoloration, and surface wear even under prolonged exposure to sunlight and environmental elements.

- Impact Resistance: Their robust structure prevents cracking, chipping, or breakage, even under physical stress.

- Customizable Sizes: Tile corner strips can be manufactured in a wide range of sizes and profiles (e.g., round edge, square edge, angle edge) to perfectly match specific project needs.

- Ease of Cleaning: Their smooth, non-porous surfaces allow for easy maintenance and cleaning, supporting hygiene especially in wet areas like bathrooms and kitchens.

The use of premium-quality raw materials and advanced manufacturing techniques gives these strips a long operational life, making them a cost-effective solution for both residential and commercial installations.

Applications

Tile corner strips significantly enhance both the mechanical strength and aesthetic quality of tiled surfaces:

- Edge Protection: Safeguard tiles against chipping, cracking, and physical impact over time.

- Safety Enhancement: Cover sharp tile edges to prevent injuries during regular use, especially in high-traffic or family environments.

- Design Enhancement: Seamlessly integrate with the tile or stone design, offering an elegant, continuous finish that complements the overall décor.

- Structural Stability: Assist in maintaining the structural integrity of tiled surfaces by reducing vulnerability at corner joints.

- Versatility of Use: Applicable across a wide range of surfaces including walls, floors, countertops, staircases, and external facades.

- Innovative Applications: Increasingly used in creative designs such as decorative wall panels, feature walls, and modern minimalist architecture.

Tile corner strips not only serve practical needs but also open new aesthetic possibilities in contemporary interior and exterior design.

How to Use Tile Corner Tape

Installing tile corner strips is a straightforward yet crucial step in achieving a professional tile finish:

- Preparation: Before installation, accurately measure and cut the corner strips to the required lengths using appropriate cutting tools (e.g., hacksaw for metal strips, heavy-duty scissors for PVC).

- Placement: Embed the corner strip into the tile adhesive applied at the junctions or corners where tiles meet. Ensure that the strip is fully seated and properly aligned.

- Tiling Over: Install the adjacent tiles snugly against the corner strip, ensuring that the grout lines are uniform and the surface remains flush.

- Final Adjustment: Before the adhesive sets, adjust the position of the strip if necessary to ensure perfect alignment.

- Grouting: Once the adhesive cures, proceed with standard grouting, ensuring the edges around the strip are neatly filled and wiped clean.

Corner strips integrate into the overall tile installation and become a permanent part of the surface, offering lasting benefits without requiring frequent maintenance or replacement.

Tile Corner Strip Consumption

The quantity of tile corner strips required for a project depends on several factors:

- Surface Dimensions: Measure the total perimeter length where edge protection or decorative finishes are needed.

- Tile Size and Layout: Large format tiles may require fewer joints and strips compared to smaller tiles.

- Design Complexity: Intricate designs with multiple corners, niches, or staircases will increase the strip requirements.

- Overlap and Waste Factor: Allow for at least 5–10% extra material to accommodate cutting losses, mistakes, or future repairs.

For precise estimation, a detailed layout plan should be developed, and all dimensions accurately calculated before procurement.

Packaging

Tile corner strips are typically customized based on project specifications:

- Length Options: Standard lengths are often 2.5 meters or 3 meters, but custom cuts can be arranged upon request.

- Protective Wrapping: Each strip is individually wrapped or packaged in bulk to prevent scratches, dents, or surface damage during transportation.

- Bulk Supply: Available in cartons or pallets for larger construction projects.

Custom branding, color matching, and specialized packaging solutions are available for wholesale buyers and large-scale projects.

By integrating tile corner strips into your tiling projects, you achieve a significant upgrade in aesthetics, safety, and durability — transforming an ordinary installation into a flawless, professional masterpiece.

Reviews

There are no reviews yet.