OM waterstop

Description

OM waterstop

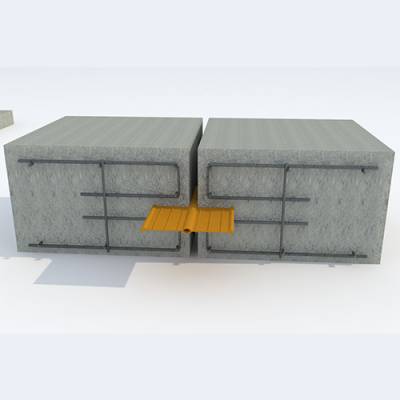

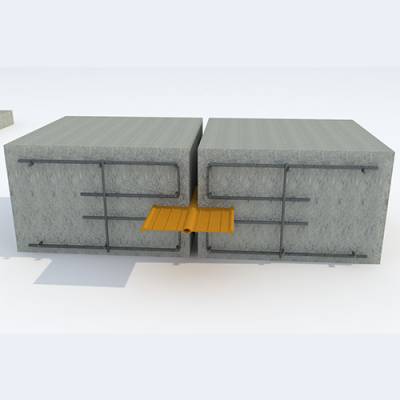

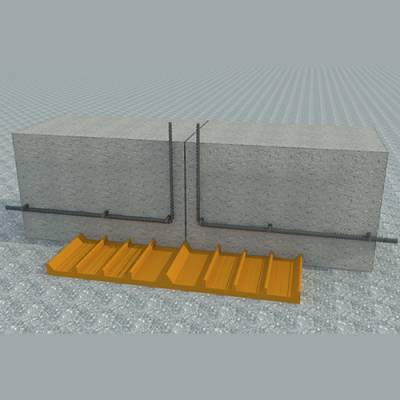

OM water stop is designed and manufactured for use in contractile and expansion seams with high static pressures. The perforated wall waterstop in its transverse center has a hole or hole that has been extended along the waterstop and is responsible for controlling the stresses caused by contraction and expansion of the structure.

Features:

- High flexibility in the direction of length and width

- Resistant to acids and alkali materials

- Structure life time

Applications:

- Preventing water passage in executive and expansion seams of structures

- Sealing of dams for concrete channels and pipes

- Sealing artificial pools and lakes

packing

| description | Thickness mm | DThe feedback detection | Packaging |

| OF Waterstop 30 | 5 | 300 %،240 ،270 | 25m |

More and more detailed explanations:

OM Waterstop – Engineered Seal for Structural Expansion Joints and High-Pressure Applications

OM Waterstop is a high-performance sealing profile specially engineered to provide durable and watertight protection in construction and expansion joints exposed to static water pressure and structural movement. This advanced thermoplastic waterstop is designed with a central perforated or hollow core that extends longitudinally across its body, allowing it to absorb and distribute mechanical stress caused by the natural shrinkage, expansion, or shifting of concrete structures.

Due to its specialized geometry and elastomeric material composition, OM Waterstop performs a dual role — not only acting as a barrier against water infiltration but also as a mechanical stress buffer within structural seams. It is ideally suited for hydraulic structures and heavy-duty concrete applications where long-term durability and performance are critical.

Key Features and Advantages

- High Multidirectional Flexibility: Offers superior elongation and flexibility both along its length and width, accommodating dynamic movements in concrete without tearing or detachment.

- Optimized Stress Relief Design: The integrated hollow core acts as an expansion chamber, effectively managing stress concentrations resulting from thermal or structural movements.

- Excellent Chemical Resistance: Engineered to resist corrosion and degradation when exposed to aggressive substances including acids, alkalis, industrial wastewater, and saline water.

- Long Service Life: Manufactured from weather- and aging-resistant polymer compounds that remain stable over decades, even in submerged or buried applications.

- Strong Adhesion and Bonding Surface: Compatible with both pre-cast and cast-in-place concrete systems. The surface pattern enhances grip and bonding with surrounding concrete.

- Easy to Weld and Join: Can be heat-welded or joined with factory-molded end pieces to create custom lengths and seamless transitions at corners or intersections.

- UV and Ozone Stable: Performs reliably even in outdoor applications and exposed environments.

- Non-toxic and Environmentally Safe: Safe for use in potable water structures and environmentally sensitive projects.

Typical Applications of OM Waterstop

OM Waterstop is widely implemented across a broad range of infrastructure, hydraulic, and civil engineering projects, especially in joints where pressurized or standing water is present. Some of its most common applications include:

- Waterproofing Construction and Expansion Joints: Used in slabs, walls, and joints to prevent leakage and maintain structural integrity in water-retaining structures.

- Dams and Spillways: Ideal for sealing joints in large-scale hydro-engineering systems exposed to high hydrostatic pressure.

- Underground Structures: Provides a watertight seal in tunnels, basements, culverts, and retaining walls.

- Concrete Channels and Stormwater Drains: Maintains channel continuity while allowing thermal movement without leaking.

- Artificial Ponds and Lakes: Prevents seepage through construction joints in landscaped or recreational water bodies.

- Water Treatment Plants: Protects tanks and reservoirs used for industrial and municipal water management from chemical or physical leakage.

- Pipe and Conduit Penetration Sealing: Ensures leak-free transitions between concrete walls and embedded pipes.

Technical Specifications

| Description | Thickness (mm) | Stretchability (%) | Packaging |

|---|---|---|---|

| OF Waterstop 30 | 5 | 240%, 270%, 300% | 25 meters/roll |

All OM waterstops are available in custom profiles and sizes upon request, ensuring compatibility with various project specifications, joint widths, and environmental conditions.

Installation Guidelines

To achieve maximum effectiveness and structural sealing performance, OM Waterstop must be installed with precision during the concrete forming phase:

- Positioning: The waterstop should be securely fixed at the joint centerline, ensuring equal embedment in adjacent concrete pours.

- Fixing Methods: Use rebar ties, clips, or special clamping tools to hold the waterstop in place during the pour.

- Heat Welding: Joints and connections between lengths should be heat-welded using appropriate tools and procedures to avoid discontinuities or leaks.

- Concrete Placement: Care must be taken to compact concrete properly around the waterstop to eliminate air pockets or voids.

- Overlap Zones: Where necessary, overlaps should be at least 100 mm and welded using compatible sealing compounds or mechanical couplers.

Packaging and Availability

OM Waterstop is supplied in standard 25-meter coils and shipped in protective wrapping to prevent contamination, distortion, or UV damage before installation. Additional packaging sizes or bulk rolls are available upon request for large-scale projects.

Conclusion

OM Waterstop is a critical component for ensuring water-tight integrity in concrete joints exposed to hydrostatic pressure and structural movement. Its advanced design and resilient material formulation make it a top-performing solution for dams, tunnels, basements, canals, tanks, and reservoirs.

Whether you are working on a complex infrastructure project or a high-demand waterproofing scenario, OM Waterstop provides the durability, elasticity, and reliability you need to protect your structure from leaks, corrosion, and long-term degradation. Backed by rigorous quality control and compliant with international standards, it remains a preferred choice among engineers, contractors, and waterproofing specialists across the industry.

Reviews

There are no reviews yet.