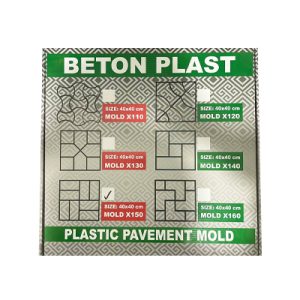

MOLD X150

Description

MOLD X150

Mould of plastic paving mold model MOLD X150 with the outer size of 4040 cm and height of 4 cm and blade thickness of 6 mm is produced from very durable ABS plastic material, and by it can be flooring a variety of villas and houses, parks and urban green spaces, garden walking path and sidewalks along streets and … It was done easily and without any special needs.

Features:

- plastic paving plastic mold model MOULD X150 is made of very durable ABS plastic and has a very high resistance to various weather and temperature conditions.

- The use of ABS resistant and quality plastic materials in the production of cement paving mold model MOLD X150 will have a very strong reason for high abrasion resistance against contact with mortar and concrete during grouting or molding.

- Possibility to use different colored cement mortar in each of the mould cells of MOULD X150 to increase the beauty of the flooring of the enclosure

Package:

1 pcs in box

Product Description – Cement Paving Template Model MOLD X150

What is the MOLD X150 cement paving mold?

The MOLD X150 concrete floor mold is a square mold with a square outer appearance and linear internal stiffeners, which is modeled and produced with a geometric form of eight rectangles at various angles. This model of villa courtyard floor mold is also called a brick design. The MOLD X150 cement paving mold has an outer size of 40*40 cm and a height of 4 cm, and is also produced from durable ABS plastic with a blade thickness of 6 mm. With this concrete paving mold, flooring of various villa and house areas, parks and urban green spaces, garden walkways and sidewalks along the street, etc. can be easily implemented without having any special skills or expertise. Using plastic flooring molds for landscaping and paving, in addition to being easy to implement, has the ability to easily implement more beautiful flooring using colored mortars. For example, in this model of paving template, mortar can be poured in different directions with different colors. As mentioned, the geometric shape of this concrete flooring template is designed and produced with a square outer perimeter and linear center blades. This plastic flooring template is designed so that the templates can be arranged together from different directions and the design can be expanded. The outer dimensions of this model of paving template are a square with dimensions of 40*40 centimeters, which can be arranged and expanded from all sides, and by arranging in different directions, various geometric forms can be formed by arranging the concrete flooring template model MOLD X150 together.

This flooring template is used for paving areas, concrete flooring, and cement covering of walkways in the yard of villas and houses, gardens, green spaces, and sidewalks along the street. Also, the MOLD X150 plastic concrete paving mold is the easiest possible way to floor the environment compared to all other conventional methods such as installing mosaics or pouring concrete and using ready-made concrete flooring, etc.

The MOLD X150 plastic concrete floor template is used for flooring public and urban environments such as parks and green spaces. It is also the best and most affordable alternative to all common options and methods such as mosaic work, concreting or using flooring with the help of ready-made concrete floors and concrete washes, etc. It will create a much more desirable and beautiful final result than the methods mentioned above.

In general, this paving mold is a piece of plastic mold designed for paving with concrete and mortar. This piece is made of durable ABS plastic, which is durable and resistant to weather conditions and temperature changes. You can use this paving mold easily and without any special skills. Also, this piece of plastic mold can be washed with water and a brush, and there is no need for special acidic detergents to separate the mortar and cement from the desired mold.

Special advantages of the MOLD X150 cement flooring template

What are the advantages of the MOLD X150 cement flooring template?

- The MOLD X150 plastic concrete paving mold is made of durable ABS plastic and has a very high resistance to various weather and climate conditions.

- The MOLD X150 plastic concrete floor molds are highly reusable and can be used in many ways. If properly maintained, they can be considered a permanent work tool for respected contractors.

- The plastic cement flooring mold produced by Beton Plast Chemical Company has high resistance to applied pressure and impact force and does not break or crack easily.

- The use of highly durable, high-quality ABS plastic materials in the production of the MOLD X150 cement paving mold ensures that it has very high abrasion resistance against contact with mortar and concrete during mortar pouring or mold removal.

- When pouring mortar or taking out molds, cement or concrete mortar will not stick to the plastic paving mold.

- When pouring mortar into the mold or removing the plastic mold for cement flooring after the initial setting of the cement mortar, the MOLD X150 plastic cement paving template will not break or fill up.

- To enhance the beauty of the area’s flooring, it is possible to use different colored cement mortars in each of the MOLD X150 mold cells.

- The plastic flooring template can be easily washed with water and a brush and does not require the use of any special acidic detergent to remove mortar and cement from the plastic paving template.

- There is no need for foundation, and the desired surfaces are leveled before paving the floor with the help of plastic concrete paving molds, model MOLD X150.

- It has the ability to form a patterned and embossed cement coating and concrete walkway on uneven and sloping surfaces using a concrete flooring template, without the need for special substructure or surface preparation, initial slope grading, or bedding.

- It is possible to use several models of plastic cement flooring templates simultaneously to create a more beautiful floor and to use various geometric designs in flooring using the concrete paving method using special molds.

- It is possible to plant grass or pour gravel into the empty space between the concrete paving cells or between their gaps to enhance the beauty of the flooring surface using a plastic concrete flooring mold.

How to pave the floor using the MOLD X150 concrete floor mold

How to use the MOLD X150 concrete floor mold?

- One of the important principles for paving the area with plastic concrete flooring molds is the special conditions of the cement mortar for pouring the mortar into the molds. The grade of the mortar used for flooring should not be less than 300, and it is recommended that the normal grade for making concrete paving mortar be 350.

- Flooring with a plastic concrete paving template is the use of mortar or concrete with a slump of 4 to 6 to pave the area with a plastic cement paving template. If you use concrete with a high slump and fluidity, the work cycle and demoulding time will increase, and if there is excess water in the mortar, it may be absorbed by the ground before the hydration process is performed, and the mortar or paving concrete will not have the desired strength after drying.

- Lubricate the plastic concrete floor molds with appropriate oil or diesel before arranging and pouring cement mortar.

- Depending on the number of available plastic concrete paving molds, model MOLD X150, for flooring, arrange them side by side.

- It is necessary to saturate the bottom of the cement paving molds with fresh water to prevent the ground from absorbing the water from the concrete mixture before the mortar reaches its initial setting.

- To build concrete paving, pour the required mortar into the cells of the plastic template with a trowel and level it.

- If you want to use several different colors in different cells of the plastic cement flooring mold, you can pour the mortar into the mold using smaller trowels to increase the accuracy of the work and prevent the colored mortars from mixing.

- After filling and leveling all the cells of the concrete flooring template, give the surface of the mold and mortar a few gentle taps with the palm of your hand or the sole of a trowel to vibrate it and form a denser mortar.

- Depending on the ambient temperature and weather conditions, the cement mortar should remain in the plastic mold of the paving template for 2 to 3 hours until it reaches the appropriate initial setting, so that the mortar does not lose its shape after the mold is removed. Be careful that removing the molds too early will cause deformation, and removing the molds too late will cause the concrete to be difficult to separate from the mold.

- When removing the plastic molds for cement flooring, make sure that the templates are removed completely vertically so as not to damage the patterned concrete and prevent it from possibly peeling.

- After removing the mold, it is essential to cure the surfaces paved with the cement flooring template by spraying water on the surface for at least 3 days.

- Depending on the ambient temperature and the concrete or mortar mixing plan used to construct the pavement, 24 to 48 hours after removing the concrete flooring molds, the surface can be walked on, and after 7 days, the completed surface is ready to operate and withstand heavy loads such as vehicle traffic.

- After finishing the work, wash the molds with water and a soft brush, dry them, and store them in a suitable place to be used in future projects.

Amount of MOLD X150 cement floor mold required for surface flooring

How many MOLD X150 cement floor molds are needed for surface flooring?

To determine the number of molds, it can be calculated and determined based on the size of the area to be covered with a plastic concrete floor mold and the time available to pave the floor. The greater the number of molds, the faster the execution will naturally be and the more appropriate time will be available for the initial setting of the mortar. It is recommended to use at least 2 to 4 concrete paving templates for flooring in small areas, and this can increase to 16 or more in large areas.

More products; Types of Plast Concrete Paving Molds

Reviews

There are no reviews yet.