Hydrophilia waterstop

Description

Hydrophilia waterstop

Hydrophilic waterstops are based on unvulcanized TPE rubber and are suitable for sealing executive seams. This type of product increases in volume when in contact with water, and after 14 days it increases to about 400%.

Features:

- Reduce the error rate compared to PVC water stops

- Maintain appearance and appearance even at high temperatures

- Sealing concrete structure at water pressure up to 6 bar

Applications:

- Sealing the executive seams in permanent or temporary contact with moisture of the earth, surface water, etc.

- Applied in both vertical and horizontal seams

Package:

15m Rolls

Product Description – Hydrophilic Waterstop

Hydrophilic waterstops are based on unvulcanized TPE rubber and are suitable for sealing construction joints. This type of waterstop increases in volume when exposed to water, and this increase in volume reaches about 400% after 14 days. The increase in volume in hydrophilic waterstops begins 6 hours after water penetrates the section. A notable point about hydrophilic waterstops is that they should only be used in construction joints and their use is not allowed in expansion joints. In cases where PVC waterstops have not been implemented in structures with construction joints, it is possible to replace them with hydrophilic waterstops.

In general, this waterstop is a hydrophilic material that is used in concrete structures to prevent moisture penetration. The term “hydrophilic” means that it swells when exposed to moisture. It can be stated that these products serve multiple purposes, including sealing concrete joints, formwork spacers, etc. When installed in construction joints, it swells in contact with water, creating an impermeable barrier, and more precisely, it seals the joint.

Hydrophilic waterstop packaging

Hydrophilic waterstop packaging

What is the packaging of hydrophilic waterstop?

15 meter rolls

Maintenance of hydrophilic waterstop

How long can hydrophilic waterstop be stored?

Duration: Two years in original packaging.

Conditions: Away from cold and frost, heat and direct and prolonged sunlight.

Best temperature: +10 to +30 degrees Celsius

How to use Hydrophilic Waterstop

How to use Hydrophilic Waterstop?

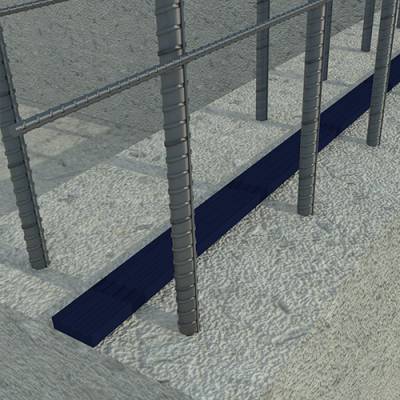

Instructions for sealing the concrete wall and floor joint:

The surface must be prepared before use.

- All surfaces must be clean, dry and free of any loose or adhering particles.

- The waterstop strip should be fixed with glue or nails in the groove in the floor concrete, then concrete should be poured a short distance after that.

Special properties of hydrophilic waterstop

What are the special characteristics of hydrophilic waterstop?

- Sealing of flat concrete structures under negative and positive water pressure

- Easy to install and run

- Reduced error rate compared to PVC water stops

- Easy installation with minimal risk of error

- Maintains shape and appearance even at high temperatures

- Non-toxic and can be used in drinking water tanks

- Affordable

- Reversible swelling against water

Hydrophilic Waterstop Applications

What are the uses of hydrophilic waterstop?

- Sealing of construction joints in permanent or temporary contact with ground moisture, surface water, etc.

- Sealing around pipes and replacing sealing flanges

- Used in construction joints in both vertical and horizontal positions

- Suitable for sealing buried and semi-buried structures

- Suitable for sealing shear concrete sections and load-bearing walls.

- Suitable for sealing foundations

- Sealing all types of construction and concrete cutting joints

Physical and chemical characteristics of hydrophilic waterstop

What are the physical and chemical characteristics of Hydrophil Waterstop?

| Color | Black |

| Volume increase ratio | 200% |

| Specific gravity at 25°C | 1/35gr/cm3 |

| Length change ratio | ±0.05% |

| Change in appearance | No abnormal condition |

| Cold resistance test | No abnormal condition |

| Size | mm20*30 |

| Volume change after 7 days in water | At least 100% |

| Volume change after 14 days in water | At least 150% |

| Percentage elongation | 300% |

| Permeability rate | 45mm |

| Standard | ASTM D 217 |

| Hydrostatic resistance | m 70 ≥ |

Technical safety of hydrophilic waterstop

What are the technical points to consider when using hydrophilic waterstop?

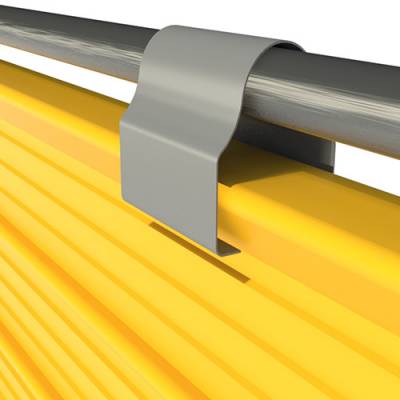

- First, place the hydrophilic water stop tape in the desired location by hand.

- Make sure the water stop is at least 8cm away from the edges.

- Attach the hydrophilic waterstop to the underlying surface with glue, nails, or screws.

- The maximum distance between nails or screws should not exceed 25cm.

- Allow at least 3cm of overlap at the ends of the rolls.

- It is recommended to apply a layer of penetrating, crystallizing, cement-based waterproofing material in a watery form to the surface beneath the wall before placing the water stop in the groove.

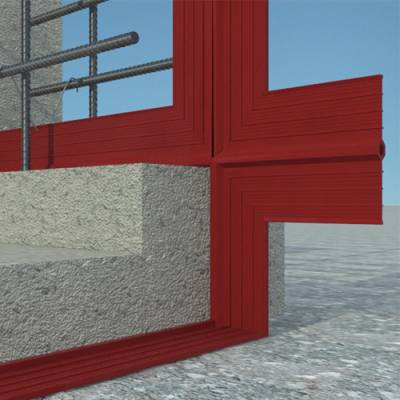

- In vertical and horizontal joints, cut the corners of the hydrophilic water stop with a cutter at a 45-degree angle and place the vertical piece of tape on its horizontal piece.

- To connect in the + shape, you can cut 4 pieces of tape at a 45-degree angle in the shape of an arrowhead. Then connect these 4 pieces together and secure them with screws, nails, or glue.

- To make a T-shaped connection, place two simple pieces of tape perpendicular to each other and secure them with screws or nails.

- Concreting should be done a short time after the waterstop tape is placed.

- If concreting is done after the hydrophilic waterstop has been installed, the waterstop surface must be covered with a suitable coating.

Reviews

There are no reviews yet.