Hard FIX spacer

Description

Hard FIX spacer

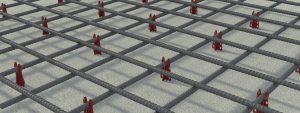

The hard fix spacer has two tentacles designed to lock the rebar inside itself. This hard fix heavy spacer is the most suitable piece for creating concrete coverings in all heavy and dense floors such as foundation, beams, shingles and bulky floors.

Applications:

- Creation of concrete coverings in all heavy and dense floors

- Spot load bearing 350 to 500 kg

- Applicable in heavy and semi-heavy surfaces

- Cost-effective and completely economical

packing :

| Name | Bar size | Packing (QTY) |

| Hard fix 25 | 32-10 | 750 |

| Hard fix 30 | 32-10 | 750 |

| Hard fix 40 | 32-10 | 500 |

| Hard fix 50 | 32-10 | 500 |

| Hard fix 50 | 32-10 | 400 |

| Hard fix 60 | 32-10 | 250 |

| Hard fix 75 | 32-10 | 250 |

| Hard fix 75 | 32-10 | 30 |

| Hard fix 100 | 32-10 | 200 |

Product Description – Hard Fix Spacer

Heavy structures such as foundations and large concrete sections have a more voluminous rebar structure and thicker rebar sizes. For this reason, the pressure exerted by the reinforcements in such sections is greater on the spacer than in other sections such as ceilings and beams, and a suitable plastic spacer must be selected to have the necessary strength to withstand the applied pressure. The Hard Fix heavy spacer is the most suitable piece for creating concrete cover in all heavy and dense floors such as foundations, beams, slabs and large-volume floors.

Hard Fixes are capable of withstanding a point load of 350 to 600 kg, and by calculating the weight of the rebar and the existing live and dead loads, an appropriate concrete cover can be created for the rebar by placing an appropriate number of Hard Fix spacers.

In general, pieces that are made and produced from very durable plastic materials are called plastic spacers. An example of this product is the Hard Fix spacer. This plastic spacer can be used as a distance holder between rebars and formwork in columns, concrete walls, structural ceilings, and can also be used to maintain the distance between rebars, the distance between rebar and foundation.

This plastic reinforcement spacer is one of the important equipment in construction, especially in concrete pouring and concrete reinforcement. This rebar spacer is specially designed for use with rebars and is used to create the appropriate distance between the rebars and the concrete formwork. The use of this foundation spacer in construction projects also increases the quality and durability of concrete structures. These simple and efficient plastic spacers play an important role in maintaining the health and safety of structures.

How to use – Hard Fix plastic spacer

How to use a rebar spacer?

The Hardfix spacer has two prongs designed to lock the rebar inside itself. The rebar is placed on the seat of the Hardfix spacer and is fixed by the locking prongs. After the rebar is placed on the seat, the bottom surface of the rebar up to the level of the floor formwork or floor concrete will create a concrete cover on the rebar, which is called a concrete cover.

Hard Fix plastic spacer consumption

What is the usage rate of Hard Fix spacers?

Semi-heavy foundations and floors:

The consumption rate is 4 Hard Fix spacers per square meter.

Extra heavy and bulky floors:

The consumption rate is 6 to 10 Hard Fix spacers per square meter, depending on the volume of the structure.

Arrows and putters:

The amount of consumption is 2 pieces at a distance of 60 to 70 centimeters from each other in length, in a row.

Important points about Hard Fix plastic spacers

What are the essential tips when using Hard Fix spacers?

- Hardfix spacers are formulated to accommodate rebar up to a maximum diameter of 32 mm, and if you are creating a concrete cover for rebar with an unconventional size and much larger than 32 mm, using plastic spacers is not a good option.

- Due to its special design and high load-bearing capacity, the rebar spacer is specifically designed for use on heavy and semi-heavy surfaces.

- It is recommended that the Hard Plastic Spacer be used for structures with a rebar diameter of at least 14, because small diameter rebars will not lock and stabilize well within the prongs of the Hard Fix plastic cover and will disrupt the exact size of the concrete cover on the rebar.

- On surfaces where there is an extra-heavy rebar network, the weight of the rebar structure per square meter must be calculated and, based on the point load-bearing capacity of the Hard Fix spacer, the required number per square meter, plus the existing live and dead loads, must be determined.

- If, after calculating the weight of the rebar network per square meter, the numbers obtained, taking into account live and dead loads, are average to low, then Max Fix spacers can be used instead of Hard Fix spacers, which is also economically cost-effective.

- Be careful not to twist or turn the rebar sideways when inserting it into the spacer, as this may cause the plastic spacer prongs to break.

Reviews

There are no reviews yet.