Flat floor waterstop

Description

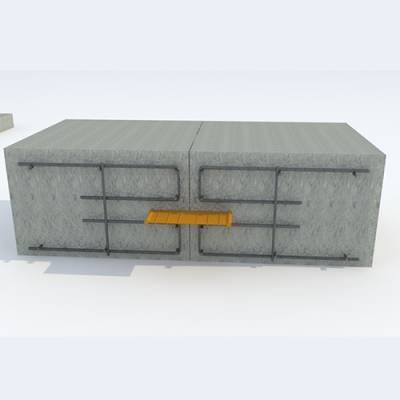

Flat floor waterstop

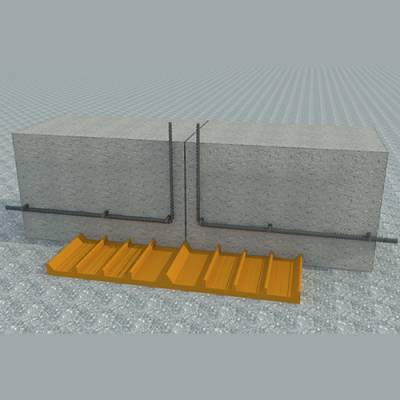

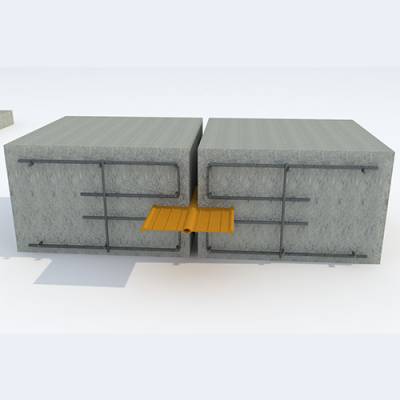

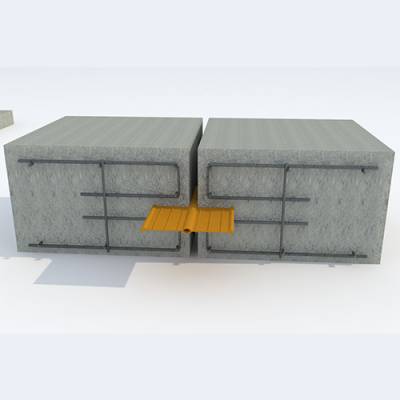

Flat floor waterstop is special for use in executive seams of concrete structures. For execution of concrete floors with executive seams, flat insole type waterstop or bed-floor waterstop is used.

Features:

- High flexibility in the direction of length and width

- Structure life time

- Tensile strength higher than standard

Applications:

- Sealing of concrete structures in the vicinity of water and liquids

- Sealing of hydraulic structures

- Preventing water passage in executive and expansion seams of structures

packing

| description | Thickness mm | DThe feedback detection | Packaging |

| Waterstop 24 | 4 | % 240,270,300 | 25m |

| Waterstop 30 | 4 | % 240,270,300 | 25m |

Flat Floor Waterstop – Seamless Protection for Concrete Joint Integrity

The Flat Floor Waterstop is a specially engineered sealing element used in the construction of concrete floor joints, particularly in executive joints of water-retaining or water-exposed concrete structures. Known also as insole waterstop or bed waterstop, this product ensures watertight sealing in horizontal seams by creating a physical barrier against the passage of water through expansion or contraction joints.

Key Features and Technical Advantages

- Superior Flexibility Across All Axes: The flat waterstop exhibits high flexibility along both its length and width, making it adaptable to dynamic loads and structural movements.

- Enhanced Tensile Strength: Designed to exceed standard tensile strength requirements, it resists tearing or deformation under high internal water pressure.

- Chemical Resistance: Manufactured from high-quality PVC or thermoplastic elastomers, the waterstop is resistant to chemicals, chlorides, sulfates, and other aggressive agents found in industrial and wastewater environments.

- Durability for Structure Lifetime: Once embedded within the concrete joint, the Flat Floor Waterstop performs effectively for the entire life of the structure, ensuring long-term protection without maintenance.

- Optimized Profile Design: The flat profile allows for uniform embedding in the concrete bed and is especially suited for large slab areas where movement control and water sealing are critical.

Applications of Flat Floor Waterstop

Flat waterstops are essential components in many types of concrete structures, particularly where water pressure or liquid movement must be strictly controlled. Typical applications include:

- Sealing Construction Joints in Concrete Floors: Used in cast-in-place slabs, large basements, foundations, and podium decks, especially where slabs are poured in multiple stages.

- Hydraulic Structures: Including water tanks, reservoirs, swimming pools, canals, and spillways, where hydrostatic pressure demands a reliable joint seal.

- Sewage and Water Treatment Plants: Provides critical protection from leakage or cross-contamination in tanks, clarifiers, digesters, and lift stations.

- Underground Concrete Structures: Such as tunnels, subways, underground parking garages, and lift pits, where water ingress must be prevented.

- Industrial Structures and Chemical Plants: Where aggressive liquid exposure requires resilient sealing materials.

Why Choose Flat Floor Waterstop?

The flat-type waterstop is a proven and effective solution for managing joint waterproofing in horizontally poured concrete. Compared to other waterstop types, it offers:

- Easier installation in base slabs and horizontal joints

- Cost-efficiency in large surface applications

- High adaptability to movement and settlement without losing sealing integrity

- Compliance with international standards for water retention and pressure resistance

Engineers and contractors trust flat waterstops for use in both non-moving (construction) joints and moving (expansion) joints, particularly in projects where long-term water exposure is a concern.

Installation Guidelines

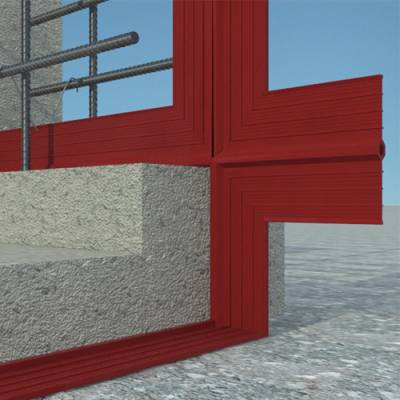

- Placement: The waterstop is installed at the joint location before the second stage of concrete pour begins. It should be centered along the joint axis to ensure full embedment.

- Anchorage: Fixing wires or clamps should be used to hold the waterstop in place and prevent shifting during concrete pouring.

- Welding and Joining: For longer lengths, waterstops can be joined using thermo-welding or hot-air welding techniques to ensure a continuous seal.

- Concrete Consolidation: Care should be taken to vibrate the concrete well around the waterstop to avoid honeycombing and ensure perfect embedment.

Technical Specifications and Packaging

| Description | Thickness (mm) | Width (mm) | Packaging |

|---|---|---|---|

| Waterstop 24 | 4 | 240 / 270 / 300 | 25 meters roll |

| Waterstop 30 | 4 | 240 / 270 / 300 | 25 meters roll |

Each roll is packed in moisture-resistant wrapping, ensuring clean delivery and long shelf-life prior to installation. Custom sizes and thicknesses can be manufactured based on project requirements and specifications.

Conclusion

The Flat Floor Waterstop is an indispensable product in modern concrete construction, playing a critical role in protecting infrastructure from water leakage and structural degradation. With its superior tensile properties, flexibility, and long-lasting performance, it offers reliable waterproofing for the most demanding applications. Whether used in hydraulic engineering, underground utilities, or industrial slab designs, this waterstop guarantees durability, performance, and peace of mind.

Reviews

There are no reviews yet.