FLAT FIX spacer

Description

FLAT FIX spacer

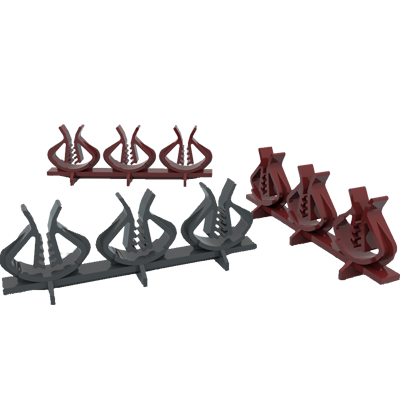

The flat-fix spacer, the top of which is exactly the same as the Mini Fix Spacer, is designed and manufactured with the difference of having a horizontal plate under the spacer. This piece has enough seats on the soft and sinking surface and it won’t go away.

Applications:•

- It will not sink on soft and sinking surface

- Able to fit rebar up to 16mm in diameter

- Capable of bearing a point load of 25 to 35 kg

- Suitable for use for structures with a diameter of up to 14 bars

packing :

| Name | Bar size | Packing (QTY) |

| Flat fix 25 | 6-16 | 1000 |

| Flat fix 30 | 6-16 | 800 |

Product Description – Flat Fix Spacer

From the description of the Flat Fix spacer, it can be stated that placing rebar on soft and sinking surfaces, such as ceilings covered with Unolith, has always been one of the concerns of respected contractors. Because the spacers installed for these surfaces usually sink into the existing soft and sinking surface due to the movement of workshop personnel and the movement of materials and concreting, and this prevents the creation of a unified cover under the rebar network. It is worth noting that generally on surfaces covered with Unolith, thermal rebars with a small diameter are used. For this reason, the Flat Fix spacer, whose upper part is exactly the same as the Mini Fix spacer, has been designed and manufactured with the difference that there is a horizontal plate under the spacer. This piece is stable enough on a soft and sinking surface and does not sink. The Flat Fix spacer is capable of accommodating rebar up to 16 mm in diameter within its prongs and, depending on the height, is capable of withstanding a point load of 25 to 35 kg.

In general, this spacer piece is designed and manufactured in such a way that it can be used on horizontal surfaces with a light rebar grid, such as soft and recessed ceilings. Using this piece on other light surfaces is not logical because the structure may experience cross-sectional weakness due to the placement of the bed below the spacer.

This piece is also one of the types of spacers used in concrete structures and construction, which is used to create the appropriate distance between the rebars and the concrete formwork. This spacer, with its special features and advantages, is an efficient and essential tool in concrete projects. Using this piece not only helps improve the quality and durability of the structure, but also increases efficiency and reduces maintenance costs.

How to use Flat Fix plastic spacers

What is the use of Flat Fix spacer?

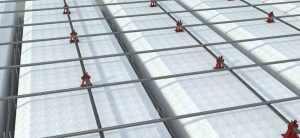

The Flat Fix rebar spacer has two serrated prongs designed to lock and secure the rebar inside the spacer. After the rebar is placed between the prongs of the spacer and seated on the seat, the rebar is locked by the prongs. The distance from the seat of the rebar to the bottom of the formwork or surface will determine the concrete cover on the rebar. A flat plate is also prepared horizontally under the Flat Fix spacer, which must be placed completely horizontally on the surface to prevent the plastic spacer from penetrating or sinking into the recessed surfaces.

Flatfix plastic spacer usage rate

What is the consumption rate of Flat Fix spacer?

On soft, concave surfaces:

The consumption rate of Flat Fix style spacers is 4 pieces per square meter.

On Unolite foams:

The amount of consumption is 2 pieces per width of the foam, which should be repeated at a distance of 50 centimeters from each other along the length of the foam.

Important points about Flat Fix plastic spacers

What are the important points when using Flat Fix spacers?

- Note that inserting the rebar into the plastic concrete spacer should not be accompanied by twisting or turning it sideways, as this may cause the prongs of the Flat Fix plastic spacer to break.

- The Flat Fix plastic spacer is designed to be used on horizontal surfaces with a light rebar grid, such as soft and recessed ceilings, and its use on other light surfaces is not logical, because the flat plate underneath may cause the structure to suffer from cross-sectional weakness.

- It is recommended to use Flat Fix plastic spacers for structures with a maximum rebar diameter of 14 mm, and for higher diameters, stronger horizontal spacers such as Max Fix spacers should be used.

- Flat Fix spacers are capable of accommodating rebars with diameters of 6 to 18 mm inside their prongs. However, a rebar network with a rebar diameter of more than 14 mm is definitely considered a medium-weight rebar network, and the use of Flat Fix spacers may not be suitable for it. However, since this product is specifically designed for use on soft and concave surfaces, and a stronger spacer with such characteristics is not currently available in the Iranian market, at least not yet, the weight of the rebar structure and the forces applied should be calculated for one square meter, and considering the point load capacity of the Flat Fix spacer, the required number of rebars should be used for one square meter.

Flat Fix plastic spacer packaging

How is the Flat Fix spacer packaged?

| Product name | Concrete coating | Rebar size | Quantity in package | Package weight |

| Name | Concrete Cover | Bar size | Packing (QTY) | WEIGHT (KG) |

| FlatFix 25 | 25 | 6 – 16 | 1000 | 8/5 |

| FlatFix 30 | 30 | 6 – 16 | 800 | 6 |

Reviews

There are no reviews yet.